1)  Double-pipe heat exchanger - simplest type of heat exchanger consists of two concentric pipes of different diameters. Following two types of flow arrangement are possible

Double-pipe heat exchanger - simplest type of heat exchanger consists of two concentric pipes of different diameters. Following two types of flow arrangement are possible

Double-pipe heat exchanger - simplest type of heat exchanger consists of two concentric pipes of different diameters. Following two types of flow arrangement are possible

Double-pipe heat exchanger - simplest type of heat exchanger consists of two concentric pipes of different diameters. Following two types of flow arrangement are possible

a) Parallel flow - both the hot and cold fluids enter the heat exchanger at the same end and move in the same direction

b) Counter flow - the hot and cold fluids enter the heat exchanger at opposite ends and flow in opposite directions

2) Compact heat exchanger

a) Designed to realize a large heat transfer surface area per unit volume

b) The ratio of the heat transfer surface area of a heat exchanger to its volume is called the area density β. Value of β > 700 m2/m3 are classified as compact heat exchangers.

c) The large surface area in compact heat exchangers is obtained by attaching closely spaced thin plate or corrugated fins to the walls separating the two fluids.

d)  The two fluids usually move perpendicular to each other, and such flow configuration is called cross-flow. There are two types cross flow

The two fluids usually move perpendicular to each other, and such flow configuration is called cross-flow. There are two types cross flow

The two fluids usually move perpendicular to each other, and such flow configuration is called cross-flow. There are two types cross flow

The two fluids usually move perpendicular to each other, and such flow configuration is called cross-flow. There are two types cross flow

i) Unmixed flow - plate fins force the fluid to flow through a particular interfin spacing and prevent it from moving in the transverse direction

ii) Mixed flow - fluid now is free to move in the transverse direction.

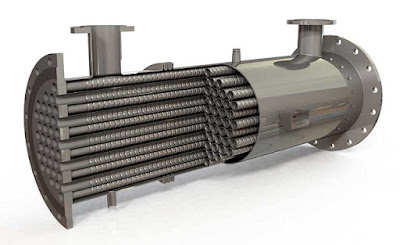

3) Shell-and-tube heat exchanger

a)  Shell-and-tube heat exchangers contain a large number of tubes (sometimes several hundred) packed in a shell with their axes parallel to that of the shell. Heat transfer takes place as one fluid flows inside the tubes while the other fluid flows outside the tubes through the shell.

Shell-and-tube heat exchangers contain a large number of tubes (sometimes several hundred) packed in a shell with their axes parallel to that of the shell. Heat transfer takes place as one fluid flows inside the tubes while the other fluid flows outside the tubes through the shell.

Shell-and-tube heat exchangers contain a large number of tubes (sometimes several hundred) packed in a shell with their axes parallel to that of the shell. Heat transfer takes place as one fluid flows inside the tubes while the other fluid flows outside the tubes through the shell.

Shell-and-tube heat exchangers contain a large number of tubes (sometimes several hundred) packed in a shell with their axes parallel to that of the shell. Heat transfer takes place as one fluid flows inside the tubes while the other fluid flows outside the tubes through the shell.

b) Baffles are commonly placed in the shell to force the shell-side fluid to flow across the shell to enhance heat transfer and to maintain uniform spacing between the tubes.

c)  Large size and weight hence not suitable for use in automotive and aircraft

Large size and weight hence not suitable for use in automotive and aircraft

Large size and weight hence not suitable for use in automotive and aircraft

Large size and weight hence not suitable for use in automotive and aircraft

d) Shell-and-tube heat exchangers are further classified according to the number of shell and tube passes involved. Heat exchangers in which all the tubes make one U-turn in the shell

i) one-shell-pass and two tube-passes heat exchangers

ii) two-shell-passes and four-tube-passes heat exchanger

4) Plate and frame (or just plate) heat exchanger

a) The hot and cold fluids flow in alternate passages and thus each cold fluid stream is surrounded by two hot fluid streams, resulting in very effective heat transfer.

b) Plate heat exchangers can grow with increasing demand for heat transfer by simply mounting more plates.

5) Regenerative heat exchanger

a) Another type of heat exchanger that involves the alternate passage of the hot and cold fluid streams through the same flow area. They are of two types

i) Static-type regenerative heat exchanger

(1) Porous mass that has a large heat storage capacity, such as a ceramic wire mesh. Hot and cold fluids flow through this porous mass alternatively. Heat is transferred from the hot fluid to the matrix of the regenerator during the flow of the hot fluid, and from the matrix to the cold fluid during the flow of the cold fluid

(2) The matrix serves as a temporary heat storage medium.

ii) Dynamic-type regenerator

(1) A rotating drum and continuous flow of the hot and cold fluid through different portions of the drum so that any portion of the drum passes periodically through the hot stream, storing heat, and then through the cold stream, rejecting this stored heat. Again the drum serves as the medium to transport the heat from the hot to the cold fluid stream.

(2) The drum serves as the medium to transport the heat from the hot to the cold fluid stream.